PART NUMBER |

STRAP SIZE |

SEALS/BUCKLES |

FEET PER COIL |

COILS PER SKID |

AVERAGE BREAK STRENGTH |

CORE SIZE |

GRADE |

COLOR |

PRICE |

|

|---|---|---|---|---|---|---|---|---|---|---|

HAND GRADE |

1/2 |

9000 |

24 |

300 |

16x6 |

H |

BLACK |

|||

1/2 |

7200 |

28 |

500 |

16x6 |

H |

BLACK |

||||

1/2" |

7200 |

28 |

600 |

16x6 |

H |

BLACK |

||||

1/2" |

7200 |

28 |

600 |

8x8 |

H |

BLACK |

||||

3/4" |

4500 |

28 |

1050 |

16x6 |

H |

BLACK |

||||

5/8 |

6000' |

28 |

800 |

8x8 |

H |

BLACK |

||||

PART NUMBER |

STRAP SIZE |

SEALS/BUCKLES |

FEET PER COIL |

COILS PER SKID |

AVERAGE BREAK STRENGTH |

CORE SIZE |

GRADE |

COLOR |

PRICE |

|

MACHINE GRADE |

5mm |

23000 |

24 |

8x8 |

M |

Green |

||||

5mm |

23000 |

24 |

110 |

8x8 |

M |

WHITE |

||||

5mm |

20000 |

24 |

120 |

8x8 |

M |

CLEAR |

||||

5mm |

22000 |

24 |

8x8 |

M |

GREEN |

|||||

5mm |

23000 |

24 |

140 |

8x8 |

M |

WHITE |

||||

6mm |

23000 |

24 |

200 |

8x8 |

M |

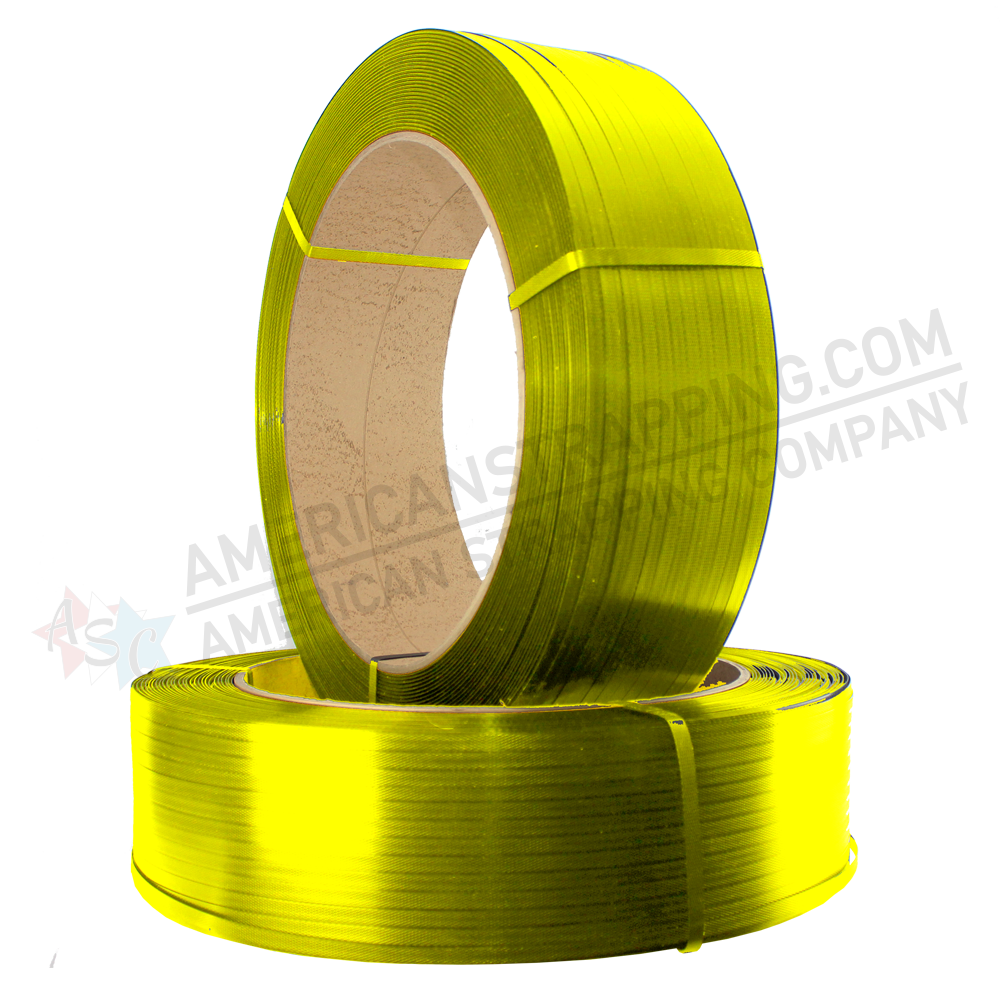

YELLOW |

||||

6mm |

23000 |

24 |

200 |

9x8 |

M |

YELLOW |

||||

6mm |

22000 |

24 |

200 |

9x8 |

M |

BLUE |

||||

6mm |

18000 |

24 |

200 |

8X8 |

M |

WHITE |

||||

3/8 |

12,900 |

24 |

300 |

8x8 |

M |

CLEAR |

||||

3/8 |

12,900 |

24 |

300 |

9x8 |

M |

CLEAR |

||||

3/8 |

12,900 |

24 |

300 |

8x8 |

M |

White |

||||

3/8 |

12,900 |

24 |

300 |

8x8 |

M |

White |

||||

3/8 |

12,900 |

24 |

300 |

9x8 |

M |

White |

||||

1/2 |

9000 |

24 |

300 |

8x8 |

M |

WHITE |

||||

1/2 |

7200 |

24 |

300 |

9x8 |

M |

White |

||||

1/2 |

9900 |

24 |

350 |

8x8 |

M |

RED |

||||

1/2 |

9900 |

24 |

350 |

8x8 |

M |

BLACK |

||||

1/2 |

9900 |

24 |

350 |

8x8 |

M |

White |

||||

1/2 |

9900 |

24 |

350 |

9x8 |

M |

White |

||||

1/2 |

7000 |

24 |

350 |

16x6 |

M |

White |

||||

5/8 |

5400 |

24 |

550 |

8x8 |

M |

WHITE |